CHONKY

Table of Contents

What Is It #

A 2nd year Engineering Physics robotics project built from 4 weeks of sleepless nights, many MANY cups of coffee, and the support of amazing TAs (and teammates!). We named our robot CHONKY.

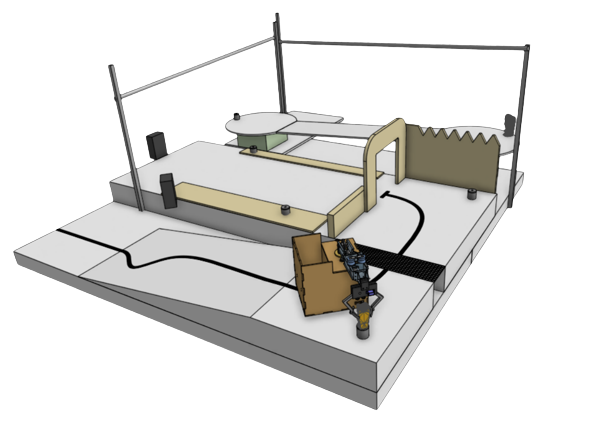

The challenge was to build a treasure-hunting robot completely from scratch that could recover lost treasures from temple ruins. To do so, the robot would need to follow tape along a ramp, cross a 6” chicken wire gap, differentiate and follow infrared signals, and pick up irregularly shaped treasure statues positioned on 2” pedestals - all in under 2 minutes.

Our Design #

After many long meetings in the basement of the UBC Hebb building, we eventually settled on 3 DOF robotic arm design with rear-wheel drive. Here is a quick recap of CHONKY’s evolution (music to come).

On the mechanical side, we had an arm that consisted of 3 independent joints, encoded using potentiometers and DC motors to provide position feedback and reinforced with high gear ratios (eg. 40:1) to withstand heavy loading. Our chassis was primarily cut from hardboard, and our servo-actuated claw was wrapped with rubber bands to provide better grasp on oddly shaped objects.

To breathe life into our mechanical systems, our PCB stacks consisted of six H-bridge and optically-isolated servo circuits to control our drive and arm motors, as well as a five reflectance sensor and three infrared bandpass circuits for tape following and infrared navigation. All wires were intentionally shielded to minimize electrical noise and interfaced with PCBs using JST connectors.

My contributions were mostly on the electrical and software end of the project. I helped breadboard the initial IR filtration and tape-following circuits, soldered the power distribution boards, and designed the architecture for our software system.

Software Architecture #

The entirety of our codebase was written in C++ using the Arduino framework, and flashed onto a STM32 Blue Pill microcontroller. To make our codebase as modular and easy-to-test as possible, we decided to use a finite state machine to organize the control logic and packed lower-level functionalities into smaller driver modules.

Soon enough, we realized that with 15 sensors and 9 motors, we were running out of I/O pins on a single Bluepill. To pivot, we took inspiration from some upper years who had competed in the 2018 competition ( Order66) to use two Bluepills and establish a master-slave communication protocol. While the master Bluepill was responsible for detecting treasures and actuating the arm, the slave Bluepill was in charge of all things drive and navigation related.

One of the most challenging tasks I faced was getting our PID for tape and IR following to work. Despite days of tuning our P, I, and D values, the mechanical response to our software was still super laggy and not improving. Eventually, we realized the problem was not in our software, but rather an issue with our motors and H-bridge circuits. Because how heavy CHONKY was, it turned out the motors could not supply enough torque below a certain speed. This was what caused the jerking-swaying motion in our PID. We also realized that we needed to decrease the capcitance value across the H-bridge so that the motor could discharge faster and change speeds faster.

Here is a snippet of our PID code:

/**

* @file PID.cpp

* @brief Class implementation for the PID feedback-control

*/

// Get reflectance sensor readings

leftReading = analogRead(LEFT_TAPE_SENSOR);

centreReading = analogRead(CENTER_TAPE_SENSOR);

rightReading = analogRead(RIGHT_TAPE_SENSOR);

// Display readings

#ifndef COMP_MODE

display->write(10, "Left Reading:" + std::to_string(leftReading));

display->write(20, "Centre Reading:" + std::to_string(centreReading));

display->write(30, "Right Reading:" + std::to_string(rightReading));

#endif

// Get tape error

bool leftOnWhite = sensorOnWhite(leftReading, TAPE_WHITE_THRESHOLD);

bool centreOnWhite = sensorOnWhite(centreReading, TAPE_WHITE_THRESHOLD);

bool rightOnWhite = sensorOnWhite(rightReading, TAPE_WHITE_THRESHOLD);

error = getTapeError(leftOnWhite, centreOnWhite, rightOnWhite);

P = error;

I += error;

D = error - lastError;

lastError = error;

// (+) modMotorSpeed = tilting right = correct to the left

// (-) modMotorSpeed = tilting left = correct to the right

int modMotorSpeed = P*KP + I*KI + D*KD;

int leftMotorSpeed = motorSpeed - modMotorSpeed;

int rightMotorSpeed = motorSpeed + modMotorSpeed;

// Set new motor speeds

leftMotor->setSpeed(leftMotorSpeed);

rightMotor->setSpeed(rightMotorSpeed);

Again, shoutout to my team (Asvin, Farhan, and Adarsh) for being the best teammates I could’ve asked for and to our favorite TA, Rudi, for being in the trenches with us the entire way.